Market mirror for tool and mold making

Special discount for members of the Marktspiegel toolmaking cooperative

- New customers & Marktspiegel members received 10% on first orders and one-time one Free Engineering service for Electrode Programming.

You can find more information about the market mirror here.

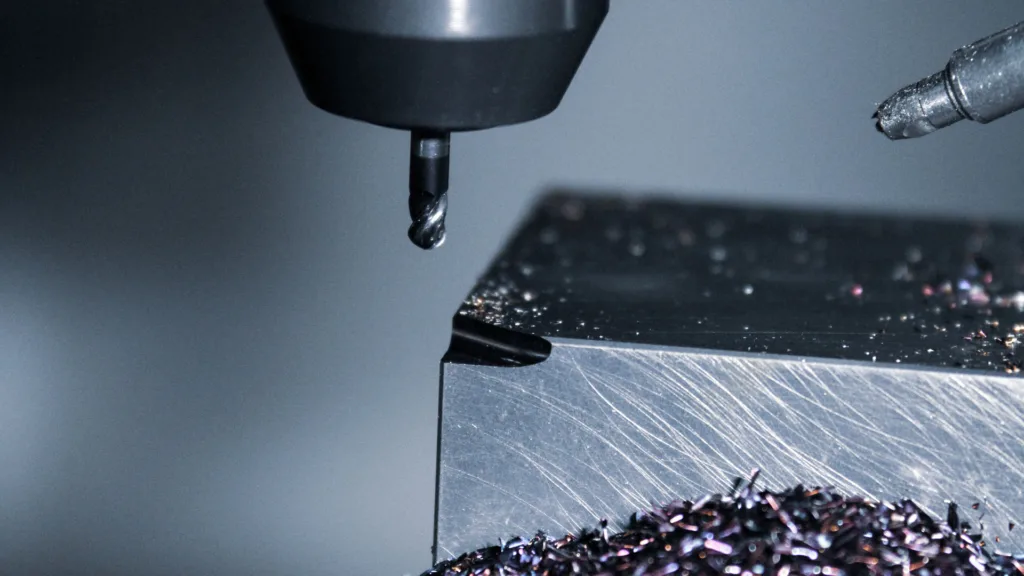

Application example graphite machining

The design of the substrate, geometry and coating are decisive for the productivity and performance of the tool. Our Graftor® is designed for cost-effective graphite machining with the for Hufschmied patented nanocrystalline diamond coating DIP® - all geometries are optimized for the material graphite.

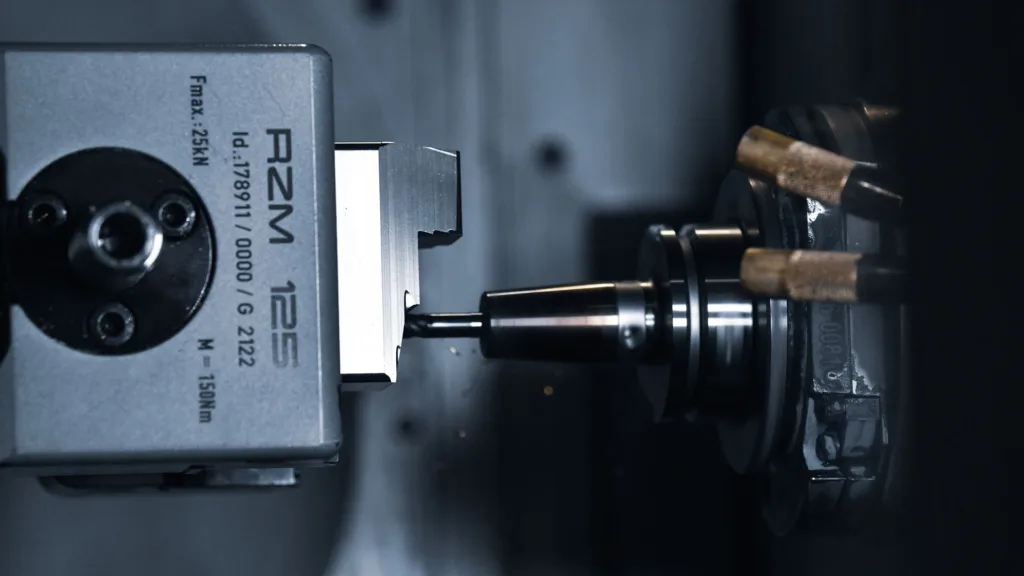

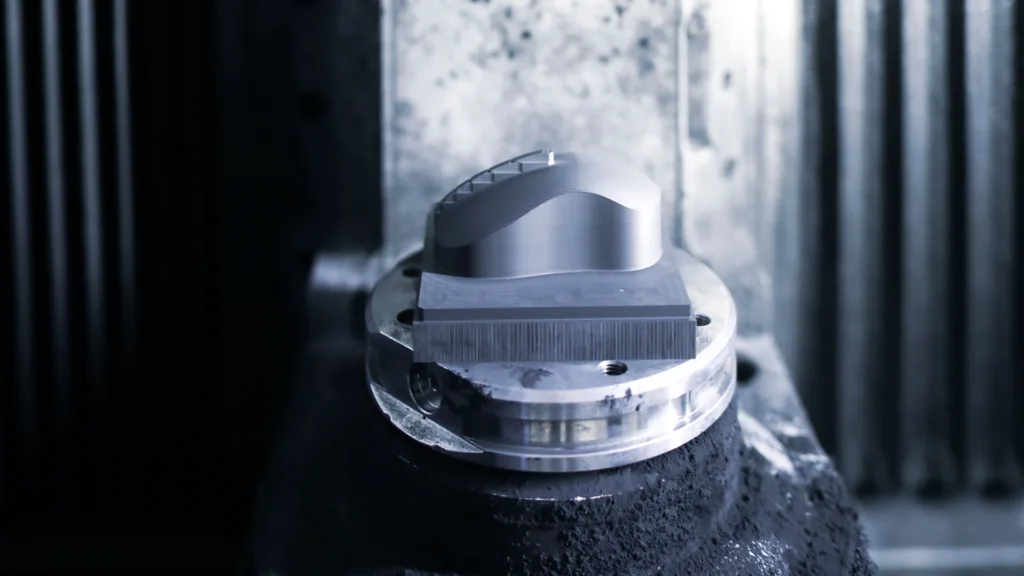

Application example steel processing: high-performance tools for hardened steel up to 72 HRC

Hard milling also plays an increasingly important role in tool and mold making. Hard milling offers great potential for supplementing process chains and can even completely replace certain work steps. However, when machining very hard special materials, the tool used is very important. Hufschmied offers you the Graphite and Hard Line in three precision versions:

- Robo-Line for highest accuracy and quality

- Business line for standard-compliant precision and quality

- Eco-Line for particularly economical milling processes

For machining hard steels Hufschmied developed the tools of the Hard-Line. The diameters of these drills and milling cutters range from 0,5 millimeters for the ball and torus milling cutters as mini milling cutters to the large multi-bladed milling cutters for cutting tool construction up to a diameter of 20 millimeters. This allows you to achieve processing results of convincing quality with components of the most varied geometries.

Industry burner

394GR

Graftor® - Graphite

- Roughing and finishing with just one tool

- Skiving cut geometry doubles the possible material removal rate, which means that smaller tools can also be used for roughing and pre-finishing

- Tool changes can be saved by using smaller tools

- 3 times the service life thanks to four compression peeling edges

- Nanocrystalline diamond layer DIP ® avoids adhesion of graphite residues on the cutting edges

Industry burner

HHF646

Hard machining up to 72 HRC

- Low tendency to cracking

- Special cutting geometry for the highest surface quality

- Cutting speed up to 400m/min in steel

- Coatings for best service life

Industry burner

HC643MUT

micro machining

- 3 cutting edge miniature tools from Ø0,2mm - 2mm

- Toric and spherical available

- Unequal tooth pitch for low-vibration use

- Soft-cutting due to special cutting geometry

- Different usable lengths available

- TL12 coating for maximum service life

HUFSCHMIED TO GO

Subscribe to our NEWSLETTER now and stay up to date.

HUFSCHMIED

Zerspanungssysteme GmbH

Edisonstrasse 11d

86399 Bobingen

Germany

Tel: + 49 8234 9664-0