Category: Hufschmied Press

-

Our donation to the colorful circle

We are proud to announce that we have made a donation of €1000 to the Bunte Kreis. The Bunte Kreis is a non-profit organization that is passionate about helping families with seriously ill children. With our donation we would like to contribute to supporting families in difficult times and giving them hope...

-

goodBIONICS relies on tools from Hufschmied

The goodBIONICS biotechnology GmbH researches new implants and also strives for innovative methods in her own dental technology laboratory. In collaboration with the Hufschmied Zerspanungssysteme GmbH proved that it is worthwhile to optimize machining processes. The machining of zirconium dioxide, cobalt chromium, titanium, PMMA and other industry-typical materials in dental laboratories is usually characterized by complete solutions.…

-

Friction stir welding tool compatible with all machine types

Hufschmied introduces solid carbide tool FSW monoblock for safe series production Bobingen, January 9, 2024 – Hufschmied Zerspanungssysteme presents the FSW monoblock, a friction stir welding tool whose shoulder and pin are made entirely of carbide. This innovation allows for consistent quality throughout its lifespan compared to conventional steel tools that can show continuous wear and tear. The reliability of the FSW monoblock pays…

-

Partnership with Röders

Hufschmied Engineering Center: Graphite and ceramic processing on Röders machine Bobingen, Soltau, September 13, 2023 – The Hufschmied Zerspanungssysteme GmbH expands the equipment of its engineering center with a 5-axis HSC machine RXP501DS from Röders GmbH. In the past, machining processes have been optimized and tested together for customers at the Soltau technical center in Lower Saxony. From November 1, 2023, this is now...

-

Hufschmied-Special tool in use at REINERT Kunststofftechnik

Post processing? Not necessary The basic structure of many branded sports seats comes from REINERT Kunststofftechnik GmbH & Co. KG, a company of the leading automotive supplier AUNDE Group. The fact that the bucket seats had to be reworked by hand after machining was a weak point in the manufacturing process for a long time. The request to the tool manufacturer Hufschmied brought the solution. REINERT manufactures bucket seats made of glass fiber reinforced…

-

Process reliability in titanium machining increases

Milling tools with SLX3 coating Parts milled from titanium play important roles in dental technology and as a basic component of implants. DIN EN ISO 22674 specifies what to work with, and dental laboratories have to see how they efficiently process such demanding materials as titanium grade 4 and titanium grade 5. Reliable processes have top priority. Novel…

-

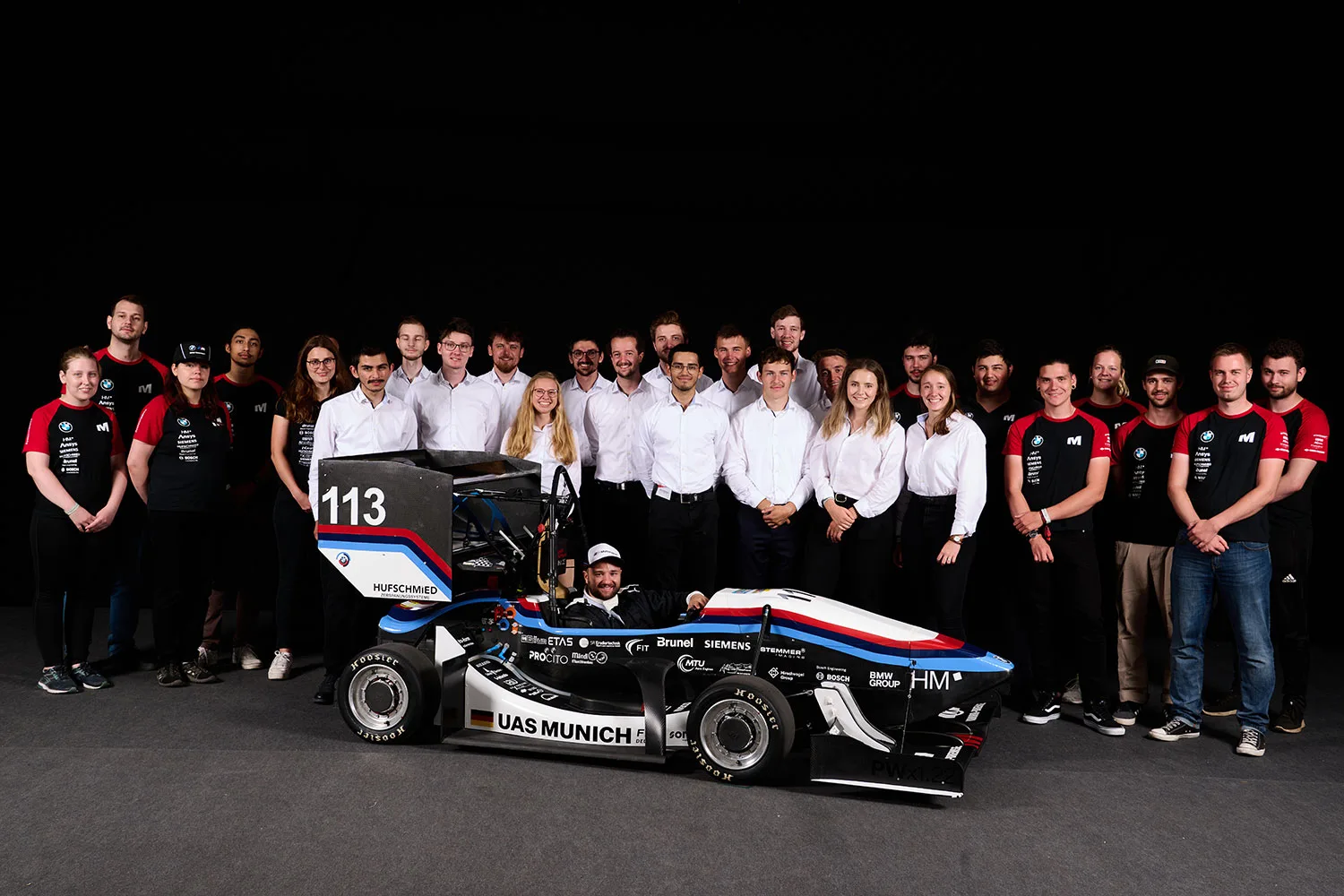

Double anniversary of the Formula Student sponsorship Hufschmied

"The monocoques are getting better and better" Bobingen, November 28, 2022 - It's been ten years Hufschmied Zerspanungssysteme GmbH Sponsor of municHMotorsport eV and Starkstrom Augsburg eV has also been supported for five years. However, the company not only provides the two successful Formula Student teams with free special tools for processing fiber composite materials and polyurethane blocks. The…

-

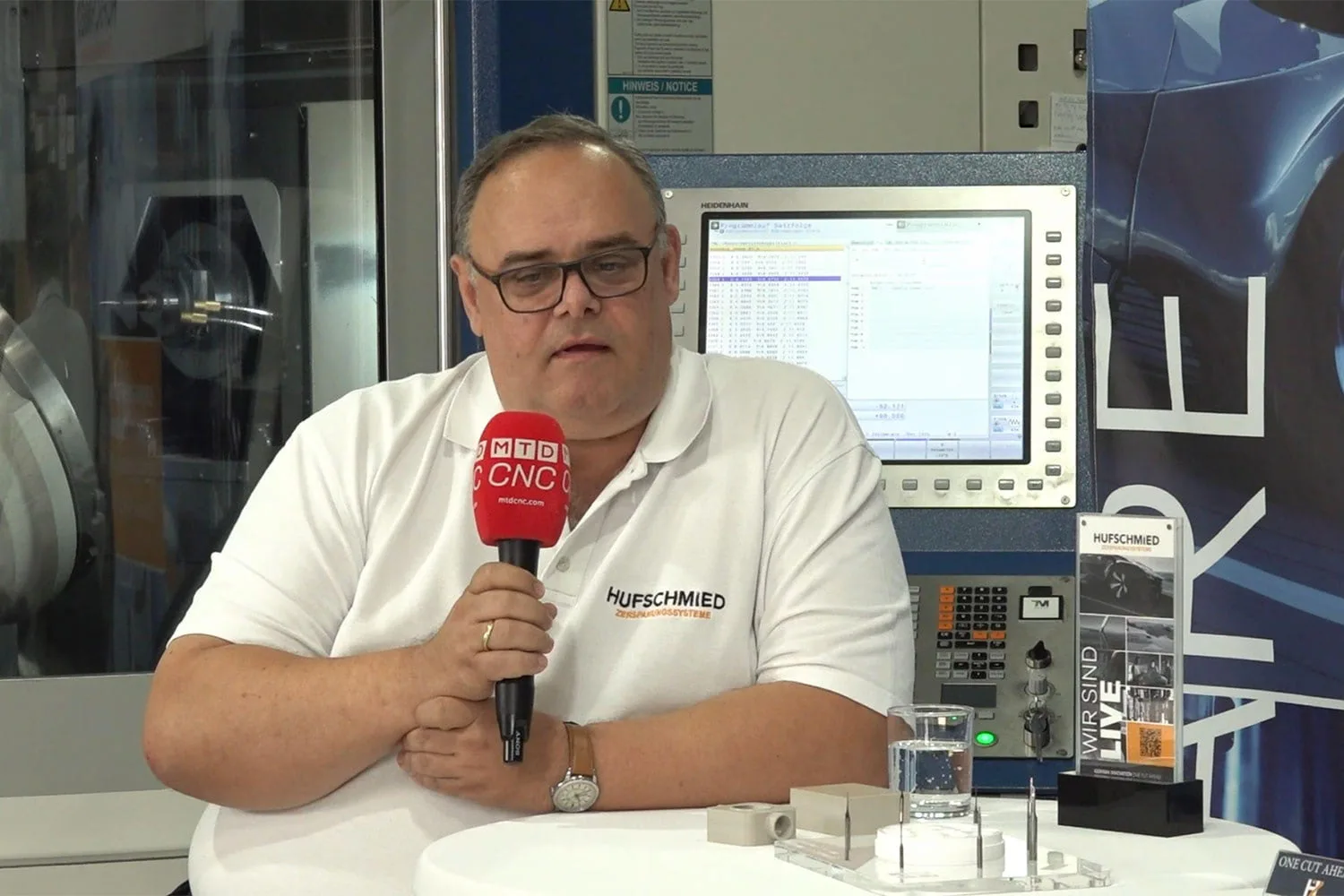

The story behind Hufschmied

Ralph Hufschmied about the start and the history behind the company Hufschmied Zerspanungssysteme GmbH.

-

Hufschmied & Aesculapian Testimonial

-

Second production site with forward-looking processes

The Hufschmied Zerspanungssysteme GmbH has opened a second production site in Sigmaringen, not far from its production site in Winterlingen. The tank hall of the former Stauffenberg barracks was converted into a state-of-the-art factory. You can read the full report here.

-

milling for research

At the end of a joint research project, the Hufschmied machining systems GmbH the innovation laboratory at the University of Augsburg a milling demonstrator. The portal milling machine, retrofitted with highly rigid axes made of carbon composite materials and special tools, was created as part of the MAI CC4fastMOVE project. The MAI CC4fastMOVE was funded by the Bavarian State Ministry for Economic Affairs, Regional Development and Energy as part of the Campus Carbon 4.0 program, which significantly…

-

Hufschmied sponsors a milling machine for the University of Augsburg

Presented as the ceremonial conclusion of a joint research project Hufschmied on March 18.03.22, 4, in the presence of regional and national politicians, presented a milling demonstrator in the 6-digit range, developed as part of the MAI CCXNUMXfastMOVE project, to the University of Augsburg. The portal milling machine, equipped with highly rigid CFRP axes and special tools for high-speed machining, enables the machining of composite materials with significantly increased efficiency...